MARCH 25, 2025

2025: How Sustainability is Reshaping Pharma Supply Chains and Thermal Packaging

As we leaped into 2025, we sought feedback from customers on their challenges on several topics, including the elephant in the room – Sustainability, and how it’s impacting supply chain decisions today.

Thank you to those who took the time to fill out the survey and provide input to your day-to-day challenges.

This article will dive into these key questions at the top of everyone’s’ minds:

- What is keeping you up at night as a temperature control supply chain professional?

- What are the top 3 challenges facing your organization when building a sustainable end to end supply chain?

- Which top 3 levers are currently being utilized in your organization to overcome those challenges?

- What type of sustainable thermal packaging are you furthest along in using or evaluating?

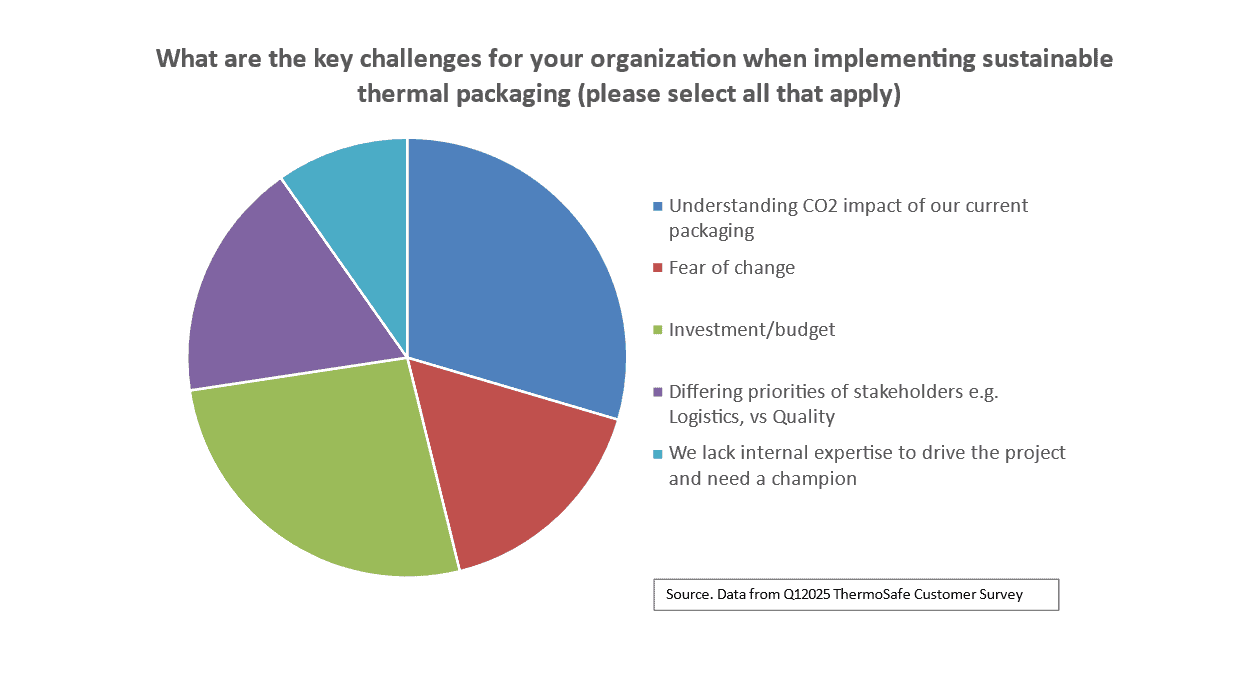

- What are the key challenges for your organization when implementing sustainable thermal packaging?

First, we started with a broad question.

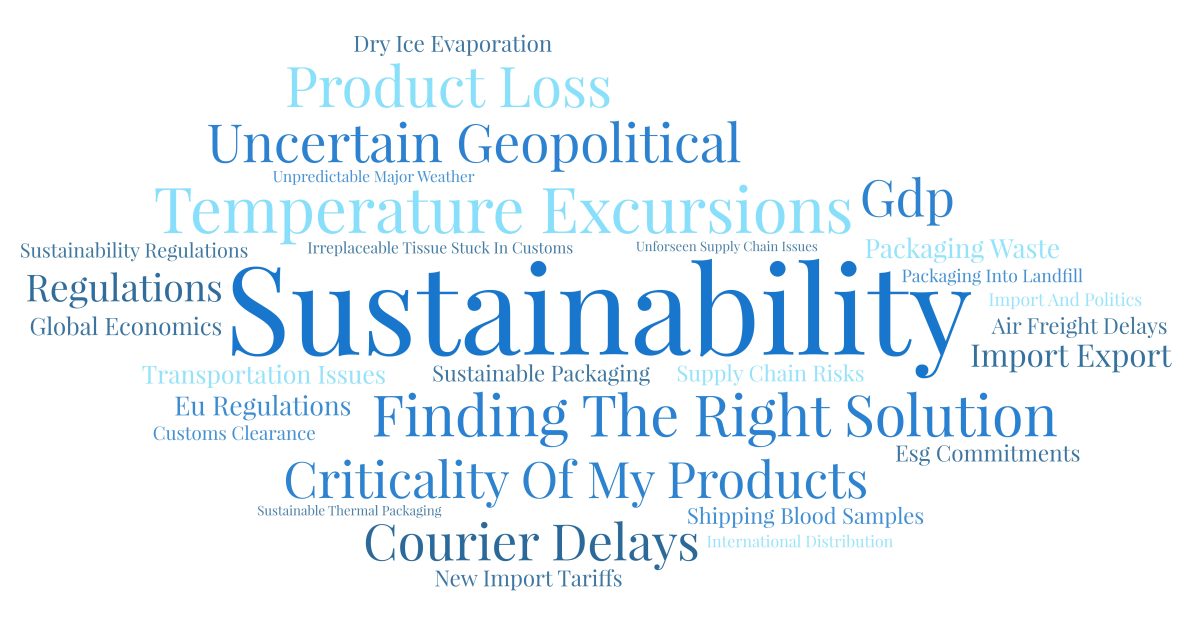

1. What is keeping you up at night as a temperature control supply chain professional?

The answers above in the word cloud reflect the myriad of supply chain, logistics and quality issues affecting professionals today. Not surprisingly, with sustainability being the #1 answer for many.

Based on these responses, pharmaceutical and other perishables supply chain professionals face a range of challenges that impact their operations. Key issues of concern include logistical disruptions such as courier delays, transportation issues, and supply chain risks, which can hinder timely deliveries. Temperature-sensitive products add complexity, with temperature excursions and dry ice evaporation posing significant risks to product integrity. Regulatory challenges, including EU regulations, sustainability regulations, and new import tariffs, further complicate global operations.

Additionally, sustainability concerns like packaging waste, ESG commitments, and sustainable packaging are becoming critical priorities. External factors, including unpredictable major weather, geopolitical uncertainty, and EU regulations, create additional instability. The high stakes involved, particularly in handling critical and irreplaceable medical products, amplify the urgency of finding the right solutions to navigate these multifaceted challenges effectively.

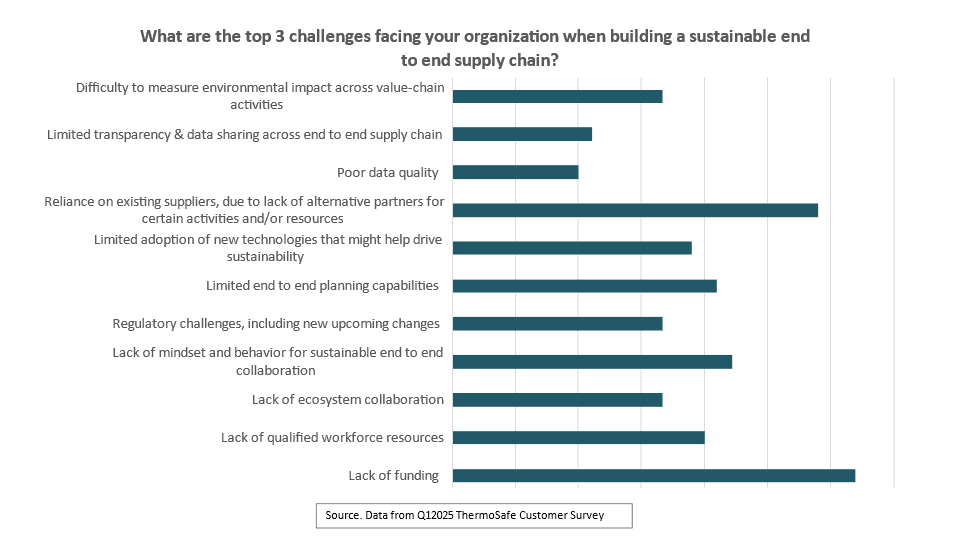

2. What are the top 3 challenges facing your organization when building a sustainable end to end supply chain?

Next, we wanted to uncover what the obstacles were on the organizational level that were preventing or stalling sustainable supply chain developments. The answers included a range from financial constraints to regulatory hurdles and operational inefficiencies. The data provides insight into the key barriers hindering progress toward a more environmentally and socially responsible supply chain, helping stakeholders identify priority areas for improvement.

Building an end-to-end sustainable supply chain is a complex endeavor, and three of the most common challenges companies face are lack of funding, reliance on existing suppliers due to limited alternatives, and a lack of mindset for sustainable collaboration. Each of these obstacles is significant on its own—but when combined, they form a reinforcing cycle that can stall or completely block progress toward meaningful sustainability goals.

Lack of funding is often the root issue, as transitioning to more sustainable materials, systems, and logistics can require significant upfront investment. Whether it’s implementing traceability tech, sourcing from certified sustainable vendors, or redesigning packaging, each step involves costs that many organizations—especially small and mid-sized ones—are not prepared to absorb without a clear ROI. This funding gap leads companies to stick with existing suppliers, even if those partners are not aligned with sustainability goals, simply because they are familiar, reliable, and often cost-effective in the short term.

However, even when funding and alternative partners are available, many organizations still struggle with a lack of mindset for sustainable collaboration. This cultural barrier stems from fragmented goals between departments or partners, misaligned incentives, or simply a lack of awareness and education on sustainability’s long-term value. Without a shared commitment to collaborative sustainability across the supply chain, it becomes nearly impossible to build the trust, transparency, and innovation needed to make real change. These challenges are deeply interconnected: limited funding discourages exploration of alternatives, entrenched partnerships make change harder, and without a collaborative mindset, no one is motivated to push the status quo. Addressing all three together is essential to unlocking scalable and impactful supply chain transformation.

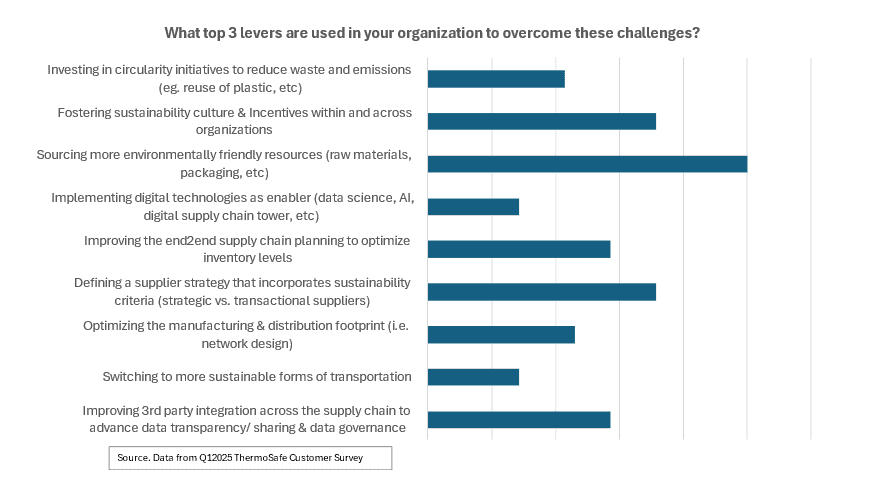

3. Which top 3 levers are currently being utilized in your organization to overcome those challenges?

It’s interesting to see that the largest lever being pulled is ‘sourcing more environmentally friendly materials, from materials to packaging’. Sustainable materials, such as recycled or renewable raw inputs, minimize resource depletion and lower greenhouse gas emissions associated with extraction and production. Additionally, opting for biodegradable or recyclable packaging helps reduce waste, supporting circular economy practices that extend material lifecycles and lower landfill contributions.

Beyond direct environmental benefits, responsible sourcing enhances supply chain resilience by reducing reliance on finite resources and volatile markets. Suppliers of sustainable materials often adhere to stricter ethical and environmental standards, improving transparency and accountability across the supply chain. This, in turn, fosters stronger partnerships, regulatory compliance, and a positive brand reputation. When integrated across procurement, production, and distribution, environmentally friendly sourcing drives efficiency, cost savings, and long-term sustainability, ensuring that the supply chain remains both competitive and ecologically responsible.

Fostering sustainability culture and defining a supplier strategy that incorporates sustainability criteria are also top levers that companies are using to overcome challenges and align throughout their supply chains. Collaboration is key when it comes to achieving carbon emission reductions, especially in Scope 3 which is typically the largest contributor and the most difficult to calculate. Working with suppliers that are already calculating their own carbon footprint or progressing with other sustainability initiatives can help companies align and also achieve their own sustainability goals. Also, incorporating sustainability into procurement can help embed this thinking into the decision-making process.

But how are practitioners tackling ‘lack of funding’? (as #1 challenge in last question)

“Creating a sustainability culture and incentives across our organization has been key to overcoming funding challenges. By embedding sustainability into our values and engaging stakeholders, we’ve been able to build a strong business case that aligns with broader goals, making it easier to secure investment”, a mid-size pharma company executive explained.

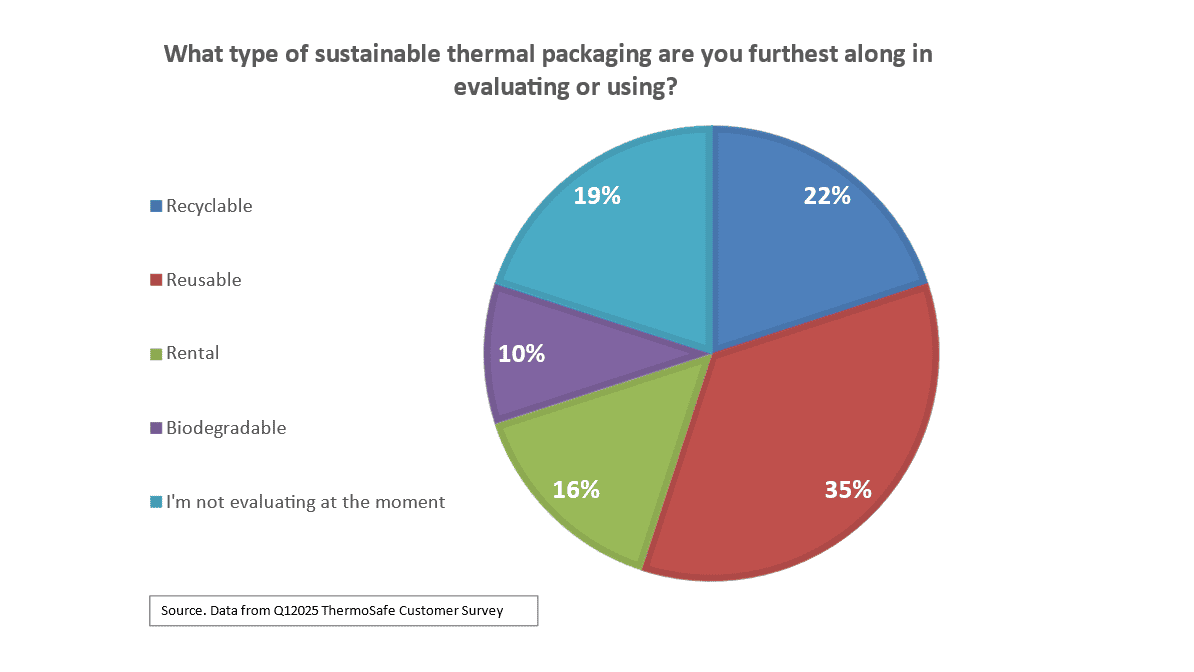

4. What type of sustainable thermal packaging are you furthest along in using or evaluating?

In 2023, when we asked this same question for the LogiPharma Sustainability Playbook survey conducted by WBR Insights, Recyclable packaging was by far the winner, at 61% of respondents already using or evaluating recyclable packaging in 2023. Reusable was 17%, Rental 0% and Biodegradable 7%.

Two years later, there is a significant increase in reusable thermal packaging consideration or use, a jump of 18%, while Rental also leaped by 16%. This is great news for the bulk reusable rental container, Pegasus ULD, and the parcel reusable rental program, Orion. It shows that supply chain organizations are improving their understanding and ability to implement new thermal packaging that results in sustainability benefits.

5. What are the key challenges for your organization when implementing sustainable thermal packaging?

One of the primary challenges supply chain organizations face when implementing sustainable thermal packaging is understanding the CO₂ impact of their current packaging solutions. Many companies lack the tools, data, or expertise to accurately assess the carbon footprint of their existing materials and processes. Without a clear baseline, it becomes difficult to measure the potential benefits of switching to more sustainable alternatives. Additionally, packaging sustainability assessments often require collaboration across suppliers, logistics partners, and sustainability experts, adding complexity to the process. Companies may also struggle with inconsistent or incomplete emissions data, making it challenging to quantify the true environmental impact of their thermal packaging and make informed decisions on improvement strategies.

Echoing the responses to question #2, another significant barrier to adopting sustainable thermal packaging is the investment budget required for new materials, technologies, and infrastructure changes. While sustainable alternatives, such as compostable insulation or recyclable liners, can reduce long-term environmental costs, they often come with higher upfront expenses. Organizations must balance these costs against financial constraints and competing business priorities. Securing executive buy-in and justifying the return on investment (ROI) can be difficult, especially if sustainability initiatives are not yet fully integrated into corporate strategy. Additionally, companies may need to invest in employee training, supplier partnerships, and compliance with evolving regulations, further adding to the financial burden. Overcoming these cost barriers requires long-term strategic planning and potential collaboration with external partners to make sustainable thermal packaging a financially viable choice.

What about evolving sustainability regulations?

Many of ThermoSafe’s pharma clients have established long-term sustainability strategies that align with global frameworks like Science-Based Targets. Our pharma customers will continue to use sustainable practices and evolve with the changing regulation/legislation landscape across the USA, EU and the world. The EU has just introduced their Packaging and Packaging Waste Regulation (PPWR) which will establish a harmonized approach to the sustainability and information requirements of packaging. ThermoSafe will be prepared to support our customers with temperature-controlled packaging solutions that comply with legislation while also optimizing for sustainability through life cycle assessments and data-driven comparisons. We have a vast portfolio of packaging solutions allowing us to be material-neutral and present the best solutions to our customers.

To learn more about US Regulations affecting sustainability decisions in global organizations, dive into this new blog post here.

How ThermoSafe can help

Sustainability remains a priority for pharmaceutical companies because they operate in a global context, where regulations, customer expectations, and corporate commitments extend far beyond any one administration’s policies.

ThermoSafe is here to help customers overcome their hurdles in uncovering their CO₂ impact of their current packaging solutions. With baseline numbers, a roadmap is laid to see where improvements can be made.

ThermoSafe has a Sustainability science-based approach including the Collaborative Design Process which helps customers understand their thermal packaging choices. Learn more about ThermoSafe’s Sustainability approach.